Description

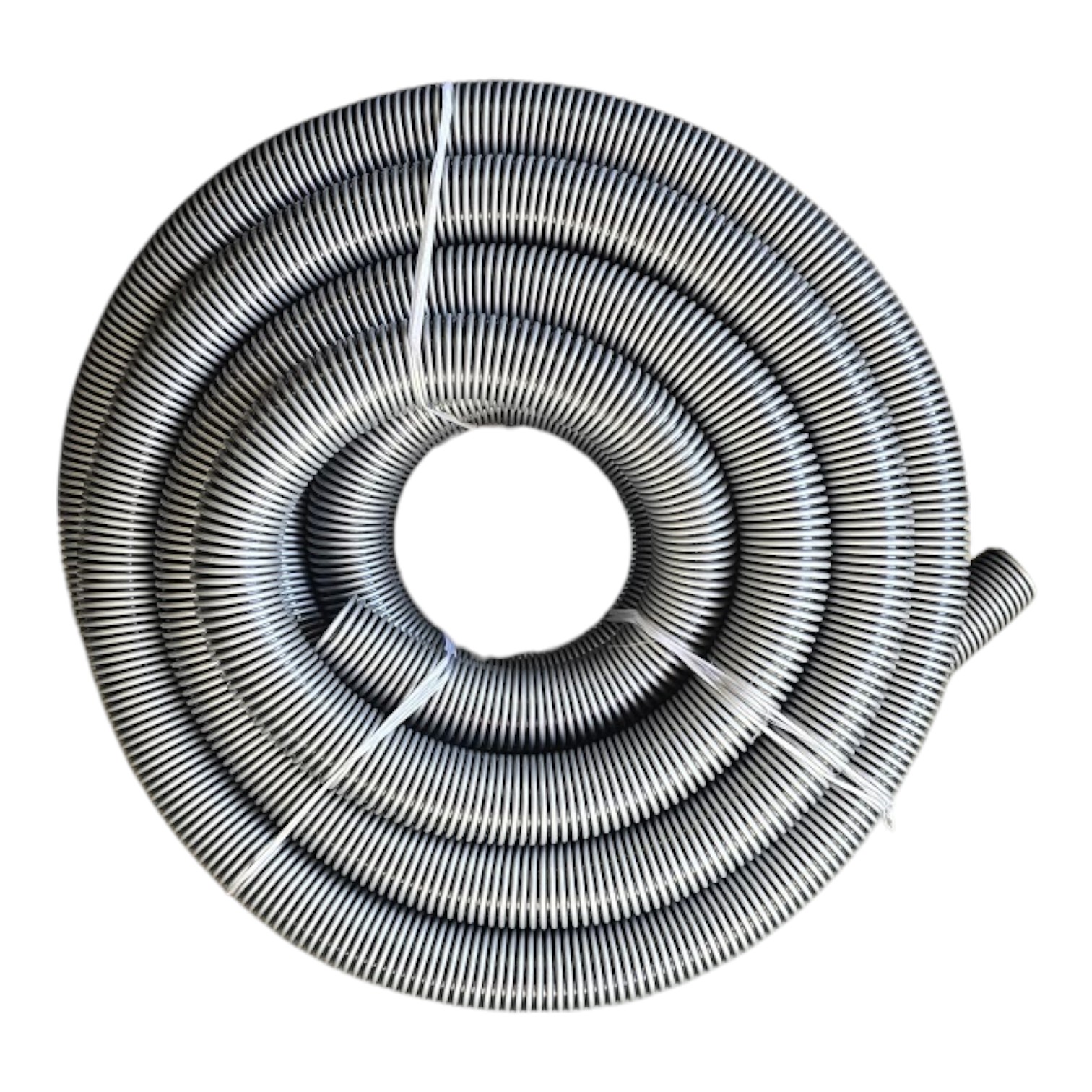

Sick of getting zapped by cheap plain old black hose >? Try this !!

When it comes to the specialized task of sucking concrete dust, the choice between an anti-static hose and a normal hose can significantly impact performance, safety, and durability. Let’s delve into the key differences between the two:

- Material Composition:

- Normal Hose: Typically made from materials like PVC (Polyvinyl Chloride) or rubber, normal hoses are designed for general purposes and may not be optimized for handling abrasive materials like concrete dust.

- Anti-Static Hose: Anti-static hoses are specifically engineered to dissipate static electricity, which is crucial when dealing with fine, powdery substances like concrete dust. These hoses often incorporate specialized materials or additives that enhance their anti-static properties.

- Static Electricity Dissipation:

- Normal Hose: Standard hoses can accumulate static electricity during use, especially when handling materials with high levels of particulate matter like concrete dust. This static buildup poses a significant safety hazard as it can lead to sparks, potentially igniting flammable dust or causing electrical shocks.

- Anti-Static Hose: Anti-static hoses are designed to prevent the buildup of static electricity by providing a path for its safe dissipation. This feature reduces the risk of sparks, mitigating the potential for accidents or hazardous situations in environments where flammable materials are present.

- Durability and Longevity:

- Normal Hose: While normal hoses may be suitable for general suction tasks, they may wear out more quickly when used to handle abrasive materials like concrete dust. The abrasive particles can cause premature wear and tear, leading to frequent replacements and increased maintenance costs.

- Anti-Static Hose: Anti-static hoses are often constructed with materials that offer enhanced durability and resistance to abrasion. They are engineered to withstand the harsh conditions encountered during concrete dust extraction, resulting in longer service life and reduced downtime.

- Efficiency and Performance:

- Normal Hose: When used for sucking concrete dust, normal hoses may experience reduced suction efficiency over time due to clogging caused by the fine particles. This can lead to decreased performance and compromised dust extraction capabilities.

- Anti-Static Hose: Anti-static hoses are designed to maintain optimal suction performance even when dealing with fine particulate matter like concrete dust. Their anti-static properties help prevent clogging and ensure consistent airflow, maximizing dust extraction efficiency.

In summary, while both normal hoses and anti-static hoses can be used for sucking concrete dust, the latter offers distinct advantages in terms of safety, durability, and performance. Anti-static hoses are specifically tailored to meet the unique challenges posed by handling abrasive materials, making them the preferred choice for industries where dust extraction is a critical requirement.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Sizes | 38mm x 10 meters, 38mm x 20 meters, 50mm x 10 meters, 50mm x 20 meters |